Working the Magic

| Page contents: |

| Uses and Users |

| Surgical Planning |

| Bid Requests |

| Scientific Models |

| Space Habitation |

Copyright © 1999, Ennex Research Corporation. All rights reserved.

Surgical Planning: Healing a Young Boy

Billy Tomlinson (not his real name) was born with a skull deformity that made his face subtlely asymmetrical. Limitations in the movement of his jaw made it difficult for him to eat certain foods. At the age of 14, surgeons had determined that it was feasible to reconstruct Billy’s skull to give him normal functioning and appearance for the first time in his life. Normally, this requires a series of complicated operations in which the doctors spend a great deal of time inspecting the deformities to determine applicable procedures and the results are not always satisfactory. But Billy’s surgeons had a magical tool at their disposal that allowed them to know exactly what they were dealing with before they took scalpel to skin. Several weeks before the scheduled surgery, the doctors received a pair of plastic models of Billy’s skull. These models were made by feeding the digital data of a CT scan to a fabber. The two skull models used by his doctors helped to ensure that Billy’s surgery would be successful, and allowed the doctors to complete their work in only one operation. The elimination of the need for additional operations was a great source of relief to Billy, to his parents, and to their insurance company. The insurance company did not approve the several-thousand-dollar cost of the fabber models as an allowable medical expense. But through experiences such as this one, where these models can literally save tens of thousands of dollars of operating room time, insurance companies are slowly coming around to understand the benefits for their own bottom lines, as well as for their policy holders, in not only allowing, but encouraging, the use of fabbed surgical planning models. Today, Billy enjoys the normal life of a healthy high school student, and he enjoys all kinds of foods he could not eat before. Billy and his parents thank God every day for the magical way fabbers have improved his life forever. |

Bid Requests: Millions of Dollars Saved through One Set of Models

One of the most dramatic stories of cost savings from the use of a fabber has been told by Peter Sferro, the man who championed the use of fabbers at Ford Motor Company. Engineering drawings for a rocker arm for a new model car were sent to four suppliers for quotes. Only three of them bid on the part. The fourth supplier was not sure, based on the drawings, how to build it. While the part was out for bid, the design was entered into CAD to allow a finite element analysis to be performed. As an afterthought, when the CAD database was available it was decided to build an SLA model, which took 16 hours. The engineer, upon receiving the model, immediately saw some problems and redesigned the push rod seat. The new design improved the quality of the rocker arm and allowed for the use of powder metallurgy to produce the push rod seat instead of more expensive screw-machine techniques. When the new car project was approved, the team decided to send SLA models of the rocker arm to the same four suppliers for requote. This time all four replied, and the supplier who had not understood the 2-D drawings came in with the lowest price by 49 cents. He later explained, “When I saw the model, I figured out an economical way to manufacture it.” With between eight and twenty million of those rocker arms produced each year, that one use of the SLA saved Ford between $4 million and $10 million annually over the life of the new design. [Story reprinted from Automated Fabrication by Marshall Burns, page 132.] |

Scientific Models: Insights Better than 15 Years of Research

For John Johnson, a structural biologist at the Scripps Research Institute, a LOM-created model of a protein turned out to be a revelation. Johnson studies the black beetle virus, a simple pathogen that infects insects, so that he can better understand more complex viruses that plague humans. “Viruses have the same problems to solve whether they are HIV or insect viruses,” Johnson explains, “and this one is very easy to work with because it has only two genes.” After 15 years of careful work, Johnson thought that he and his colleagues completely understood the black beetle virus. They knew, for example, that 180 identical copies of one protein linked together to form the virus’s geodesic dome-shaped outer capsule, they knew how those links were forged, and they could program a computer to show it. “At one level we knew everything,” Johnson says. “We could generate tables of distances and all the nitty-gritty that describes the way these proteins interact with one another, and we could look at it on a graphics system. In fact, we were satisfied with our results—up to the time we got the solid model.” Last year Johnson handed his data over to [Michael] Bailey [director of the Tele-Manufacturing Facility of the San Diego Supercomputer Center], who then built nine copies of the protein, each 20 million times actual size. When Johnson got his hands on the protein models, he assembled three into a clump, just as they assemble themselves in nature. Then, turning the proteins over in his hands, Johnson saw a hole where the three molecules met. In all his years of studying the proteins, this hole had eluded him; computer graphics couldn’t give him enough sense of depth to notice it. As soon as Johnson saw the hole in the model, he recognized that it was a perfect fit for a peglike protrusion on another surface of the three-protein chain. “There is an alignment, just like you would align things if you were fitting together pieces of wood,” Johnson says, “and we hadn’t realized it. We didn’t even know we had missed it. Now it is possible to design small molecules that can fit into that hole and block the assembly of the virus. As soon as I saw the model, I was running around like a crazy man, showing everyone how stupid we had been. I think that is going to be a fairly universal experience when it comes to looking at the assembly of subunits with these models.” [Story exerpted from A Touch of Science by Kathy A Svitil in Discover, June 1998, page 83.] |

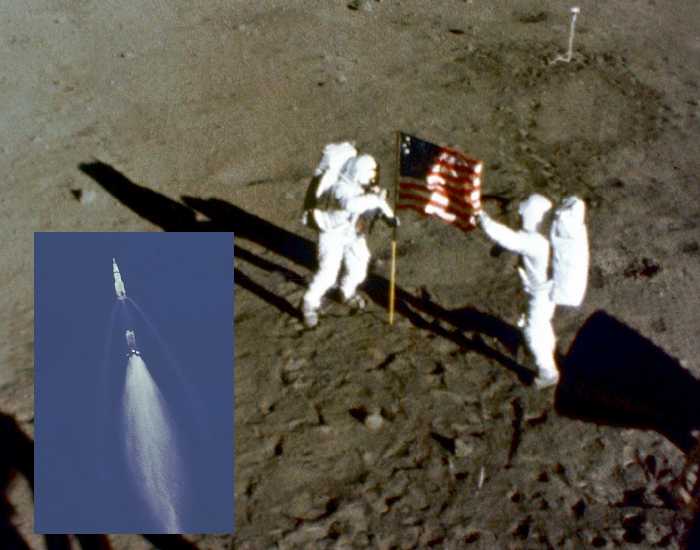

Space Habitation: Practical for First Time in History

When the European settlers came to America, they brought their hammers, axes, saws, and barrels of nails. With these tools and materials they built cabins, barns, and forts. They did not, however, bring wood, the most important construction material they would need, because they knew they would find plenty of timber at their new home site. In fact, in many cases they had to get to work cutting down trees not only to provide lumber for construction but also to provide clear land on which to build their homes and plant crops. When we go to the Moon, Mars, and the Asteroids, we know we will not find any trees or wood. But we will find plenty of other construction and industrial materials, such as iron, aluminum, and magnesium, from which we can build shelters, factories, and machinery. The presence of these materials could save us the expense of launching steel beams and aluminum habitat shells, except for one major problem. What will stand as the modern analog of the settlers’ hammers, axes, and saws? What tools can we take with us to turn celestial rocks and dust into walls and girders? Until recently, this was a “Catch-22” situation. We need refineries and foundries to process raw ore into building materials. But refineries and foundries are large, heavy facilities that consume voluminous materials in their own construction. So how can a Lunar or other celestial settlement be bootstrapped out of the indigenous soil? The answer lies in additive fabbers. As the quality and speed of fabber output steadily improves, we are gradually moving toward a time when these machines will be able to participate in the construction of large structures and make parts to be incorporated into working machinery. The ability of several processes to work with metals may allow the launch of one or a small number of fabbers to spawn the construction of an entire colony. As a commercial technology, additive fabbers are just over a decade old on Earth. The various processes are undergoing very rapid refinement and improvement. These methods present new possibilities for building up objects from celestially available materials. This new capability will allow explorers to venture forth with fabricators to build their homesteads and their industrial facilities. It has long been recognized that machines with such capability would be necessary to really make space settlement feasible, just as the European settlers needed their saws and hammers to begin building a home in America from native timber. Fabbers are the technology breakthrough that will finally crack the barrier to space habitation. [Adapted from Using Fabricators to Reduce Space Transportation Costs, by David S. McKay, Hubert P. Davis, and Marshall Burns at the Solid Freeform Fabrication Symposium, Austin, Texas, 1996.] |